Why We Need to Choose Our Interiors Fabrics More Carefully

By

1 year ago

For the sake of nature – and human health

Investigating the future of interiors fabrics – and how they could be key to our fight against climate change and environmental destruction.

The Future of Interiors Fabrics

A stand at Future Fabrics Expo

We’ve all seen the videos of discarded clothes strewn across the Atacama Desert; the documentaries about entire lakes drained to quench our thirst for new denim; and the rivers in Africa and Asia turned multi-coloured with toxic dye and untreated industrial waste. So we know the stats about the environmental impact of the textiles that line our wardrobes – but what about that of those in our wider homes?

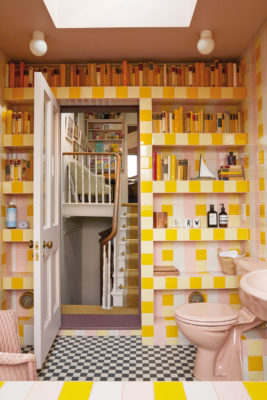

From carpets to curtains to duvet covers, our homes are filled with fibres that, like clothing, are very much part of the problem when it comes to climate change and pollution, whether they’re made from microplastic-shedding petrochemicals (polyester, nylon), or ultra-polluting cotton, or doused in toxic chemical fire retardants.

But there is a better way. There’s a quiet material revolution bubbling in the interiors world, with many industry players committing to finding less planet- and health-damaging fabrics with which to furnish our homes. Leading the way is The Sustainable Angle, the not-for-profit organisation behind the annual Future Fabrics Expo, which gathers together the world’s most innovative producers, scientists and designers, with over 10,000 materials and solutions on display. It was founded by Nina Marenzi (a judge for this year’s 50 Finest Interior Designers) in 2010 as a way of connecting sustainable fabric producers with the fashion – and now interiors – industry. ‘It’s about making it super easy for creatives to find them,’ Nina explains. ‘And it’s also about education. Most creatives, whether that’s a fashion or interior designer, haven’t studied [sustainable textile solutions] so we need to help them to make it as easy as possible, as well as inspiring.’

Highlights at the 2024 Future Fabrics Expo included Bananatex chairs made from Abacá, a species of banana endemic to the Philippines; lights made from plant roots from Rootfull; fabrics made from agricultural waste; and Säntis Textiles, which makes fabric from 100 percent pre- and post-consumer recycled fibres.

Lights by Rootfull

However, the complex nature of creating interiors schemes, choosing fabric and finding the right suppliers is a big hurdle for many interior designers, let alone individuals trying to make better choices when decorating their homes.

One of the issues, Joanna Benton of Helen Green Design (a member of the Positive Luxury-awarded Allect Design Group) says, is that the ‘choice of fabrics is so vast. As a designer you spend a long time looking for the right fabric. And then to look at the sustainability credentials of that fabric, you might have to search another really long time to find something with the same properties.’

To tackle this, Allect is setting up a material database that’s sorted into more sustainable choices, and less. Its team also looks at the accreditation of its suppliers – like Global Organic Textile Standard and the Leather Working Group – and gets them to sign a code of conduct that covers social responsibilities and fair labour conditions, ‘to make sure we’re all singing from the same page’. Other designers prioritising sustainable fabrics are Louise Bradley, who is introducing an eco-friendly range of textured linens, wools, cottons and velvets produced in Europe, and Rose Uniacke, whose in-house line uses natural, ethically sourced and sustainable materials.

However, the processes involved in building and decorating are so many and varied, with numerous supply chains, product journeys and components used, that it’s practically impossible to create a scheme that is 100 percent ‘green’.

‘You can never put the environmentally-friendly label on anything,’ says Joanna. ‘I think that’s where everyone [in the industry] gets tripped up and is scared to talk about it or say the wrong thing, because, at the moment, we’re not there yet.’

Another big challenge is that, at the moment, momentum to encourage more sustainable practices is coming from inside the industry, rather than the customers themselves. ‘I do think that clients are going to appreciate it more and more, and this is the only way forward,’ says Joanna. ‘It’s going to get bigger and better – but I think it’s probably up to us to offer solutions to the clients.’

Another big barrier is the UK’s overly stringent fire regulations, she continues. ‘It really bothers me that we have to flame retard a lot of fabrics that go into residential projects, and the toxicity involved in this.’ Homes in the UK have some of the world’s highest levels of dangerous flame retardants.

Traditional upholsterer Delyth Fetherston-Dilke, who lectures in sustainable practice at KLC, agrees. Her focus is challenging outdated UK regulations that mean home furnishings have to be treated with fire retardant chemicals – which studies have shown are toxic to human health, and the Fire Brigades Union has stated have a ‘negligible’ impact on fire safety. ‘They’re really toxic, they’re bad for the environment and they’re definitely bad for our health,’ Delyth emphasises.

As well as being potentially damaging to humans, the application of fire retardant chemicals also means fabrics and foam used in furnishings can’t then be recycled. Like Joanna, she also notes the lack of customer awareness around this, and thus a lack of demand for change, meaning many brands themselves are not pushing for it.

A Naturalmat mattress being assembled

However, one company bucking that trend is Naturalmat, the Devon-based B Corp brand that uses only wool, recycled denim and other bio materials to make its mattresses. ‘All of Naturalmat’s mattresses, beds and bedding are chemical-free, non-toxic and covered with fabrics that have passed British fire-retardant standards without being treated, thanks to the unique blend of cotton and organic lambswool that acts as a natural fire retardant,’ explains founder Mark Tremlett. Soane Britain avoids it too, only using biodegradable materials.

Naturalmat gets many of its natural materials from organic suppliers, and has set up regenerative farming programmes for its local farmers. This approach is, for Nina, the ‘ultimate goal’ when it comes to textile production. ‘[Regenerative textiles] mean that fashion and home interiors can actually have a positive impact,’ she says. ‘It’s the only goal we have to envisage for those two industries [fashion and interiors], because otherwise, we’re just ruining the planet.’

She points to a regenerative cotton agriculture and agroforestry programme set up at Lake Chad by The Circular Bioeconomy Alliance (CBA), founded in 2020 by King Charles III. It brings together partners such as LVMH and the International Rescue Committee, and part of the Great Green Wall initiative that is restoring ecosystems in North Africa. Lake Chad, once one of the world’s largest water bodies, is currently undergoing an environmental and humanitarian crisis as its water levels fall – 90 percent between 1963 and 2001 – with industrial water-intensive cotton production one of the drivers of this loss. The CBA’s Living Lab in Chad is focusing on sustainable and regenerative methods of cotton production while restoring biodiversity and creating economic opportunities for the local population.

But as well as being the right thing to do, choosing fabrics grown in a regenerative fashion is also good business sense for brands who want to succeed in the future. A 2023 report by the Boston Consulting Group found that brands that invested in regenerative materials could gain an estimated average six percent profit uplift after five years.

‘Raw materials make fashion and apparel brands,’ says the report, a statement that can easily be translated to interiors textiles, too. ‘And can break them, especially as the world confronts climate and sustainability challenges and especially because raw materials can constitute as much as two-thirds of a brand’s climate impact.’

‘What people don’t realise is it’s actually a risk management issue,’ concludes Nina. ‘Most of these fibres that grow on fertile soil [now] won’t always be available, so brands need to start looking for things that grow on marginal lands. The sooner you start shifting your supply chains, the less the risk you face, and the less steep the prices will be when you have to make these transitions.’

The industry may be moving in the right direction, but now it’s up to customers like us to demand better.